Tecna, Cersaie, Open House: System Ceramics triplicates in September 2024 with amazing innovations

September has always been a very busy time for the ceramic sector when new developments in

technology and the latest trends are presented to a vast international public.

This year, System Ceramics, the Coesia company, multiplied by three, taking the best of its know

-how to as many prestigious stages.

- TECNA (September 24-27), Rimini Expo Center (Italy), Stand B5/301 – B5/300:

showcasing cutting-edge solutions that promise to take ceramic production towards an

evolution of the highest quality. - CERSAIE (September 23-27), Bologna (Italy), Hall 33 – Stand E34: together with

Tosilab, a company specialising in interior design projects and realizations, System

Ceramics will be present at the leading trade show for surfaces and bathroom

furnishing sector. - Open House “Inside Innovation Valley” (September 18 – October 2) at the System

Ceramics Headquarters in Fiorano Modenese (Modena, Italy): an event that promises to be

an immersive experience, offering visitors a comprehensive understanding of processes

through guided tours of the facility, meetings with experts, and live demonstrations of the

machinery.

A common theme linking these three highly-awaited September events is System Ceramics’

innovation DNA, always directed towards studying possible evolutions of the ceramic sector in a

systemic and cross-cutting way to guarantee the best process solutions for partner producer

companies.

On each of these stages, therefore, the technological focus will be crucial and will relate mainly

to the pressing, decoration and end-of-line processes, presenting a range of proposals that

improve efficiency, precision and aesthetic quality.

An interesting exclusive development is proposed precisely for end-of-line: the new I-GV

(Automated Guided Vehicle), an autonomous laser-guided vehicle developed entirely in-house

and designed for the handling of load units of any size. With this solution, System Ceramics

demonstrates its desire to be ever closer to customers with a plant engineering vision of its own

design and development.

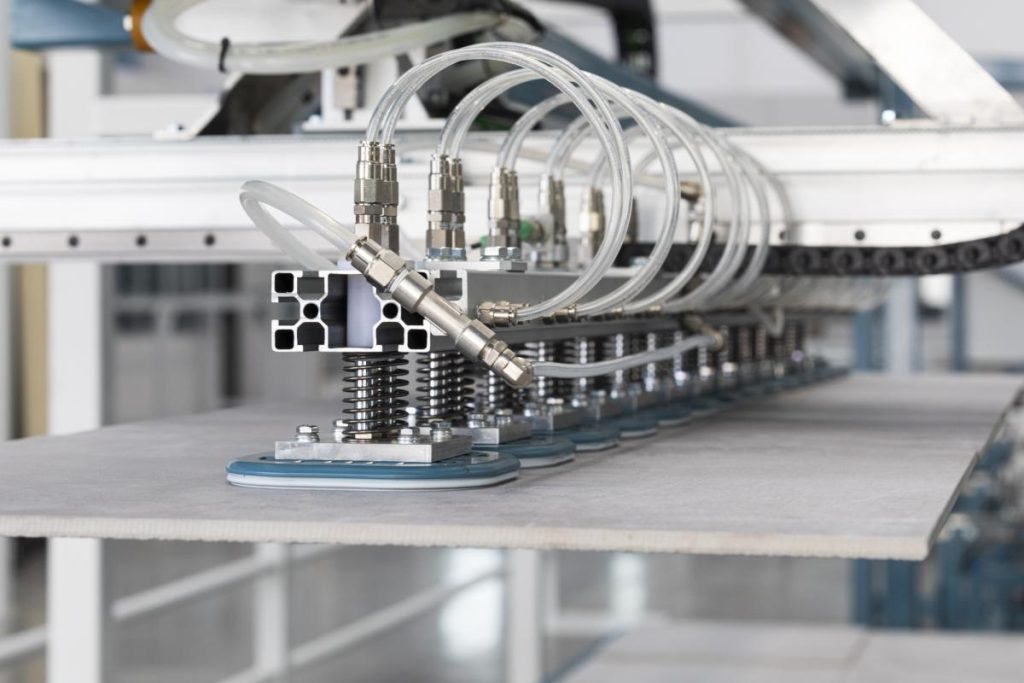

Remaining in the end-of-line area, handling is assigned to Rotostore, the 4+1 automatic robot

designed to efficiently handle the loading and unloading of fired material from the production line to

the loading beds and vice-versa. This machine uses a robotic arm with a double row of suction cups, able to lift two rows of tiles at the same time or a single heavier row. It’s a patented system,

which ensures very high performance levels.

The importance of digital decoration in the world of ceramics is increasingly surprisingly evident.

This year, System Ceramics is offering two important versions of Creadigit Infinity, whose quality is

recognized by the international market thanks to its unprecedented computing power.

In this line,

Infinity SKY is a new entry, available in two machine types – one with 4 colours and one with 8

colors – allowing for 12 and 16-bar modularity, each equipped with a pneumatic lifting

mechanism and a protection system that can be activated when not used. What distinguishes

Infinity SKY is the new self-maintenance process to keep the heads in perfect condition, ensuring

greater durability of the machine, printing over a long period, and high quality for the entire

(extensive) life cycle. The use of water-based inks, regarding which System Ceramics has been a

pioneer since 2016, also helps this process.

Also belonging to the Creadigit Infinity is Infinity DRY, the new digital grit and powder depositing

system with selective operation, which makes it possible to deposit granules and powders in

selected points on specific areas, creating numerous versions of digital designs. System

Ceramics has once more demonstrated its pioneering vision and raised the level of digital

decoration, integrating decorative digital bars and those for grit into a single module. This

permits the application of dry material in a single step, guaranteeing maximum precision and

reducing material waste and recirculation impurities to a minimum.

In the field of digital decoration, an interesting upgrade also affects the renowned Digiglaze, the

low-energy impact digital machine for the glazing of ceramic supports that can handle formats up to

large slabs, with sizes up to 1800.

Genesis, which Tecna presented as a prototype in 2022, also comes back to the fore. Today, two

years later, it has become a proven and successful solution, making full-body three–

dimensional decoration possible, with digital control of the discharge of the coloured atomized

powders in different selected points of the slab, according to the graphics set.

System Ceramics’ September presents a rich calendar of events and new developments,

confirming its sector leadership through a series of events and proposals that look to the future of

ceramics in the name of innovation.

GIPHY App Key not set. Please check settings